Hydrogen cylinders for cars

Anhui clean Energy has been dedicated to the research and development of high-pressure CHG4 composite hydrogen cylinders for vehicles, collaborating with several chinese universities and research institutions. After relentless effortswe successfuly developed 35MPa and 70MPa high-pressure hydrogen cylinders in 2024. To further enhance productquality, we invested 300 milion RMB in 2023 to build an automated plant. Our goal is to produce 35MPa and 70MPa highpressure hydrogen cylinders that meet Chinese and international high standards and launch them to the market in 2025

Hydrogen cylinder product advantages

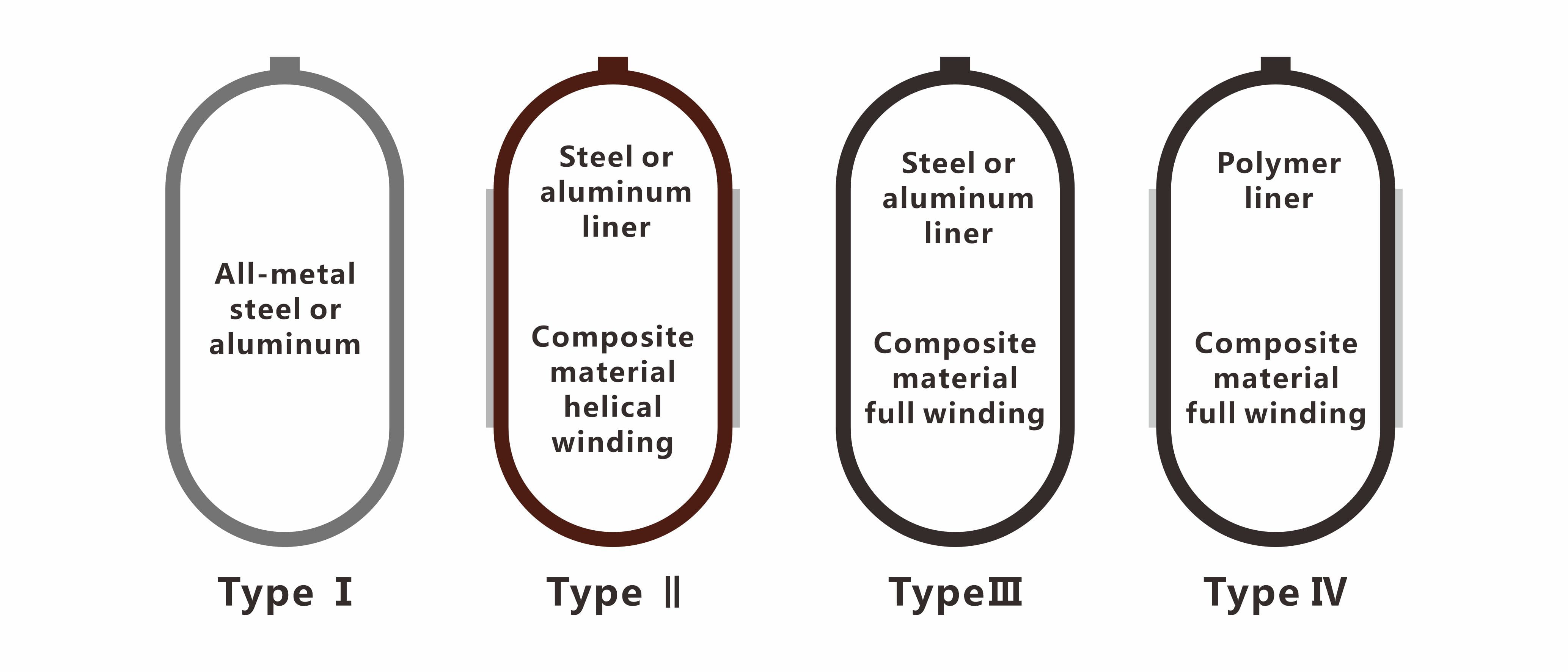

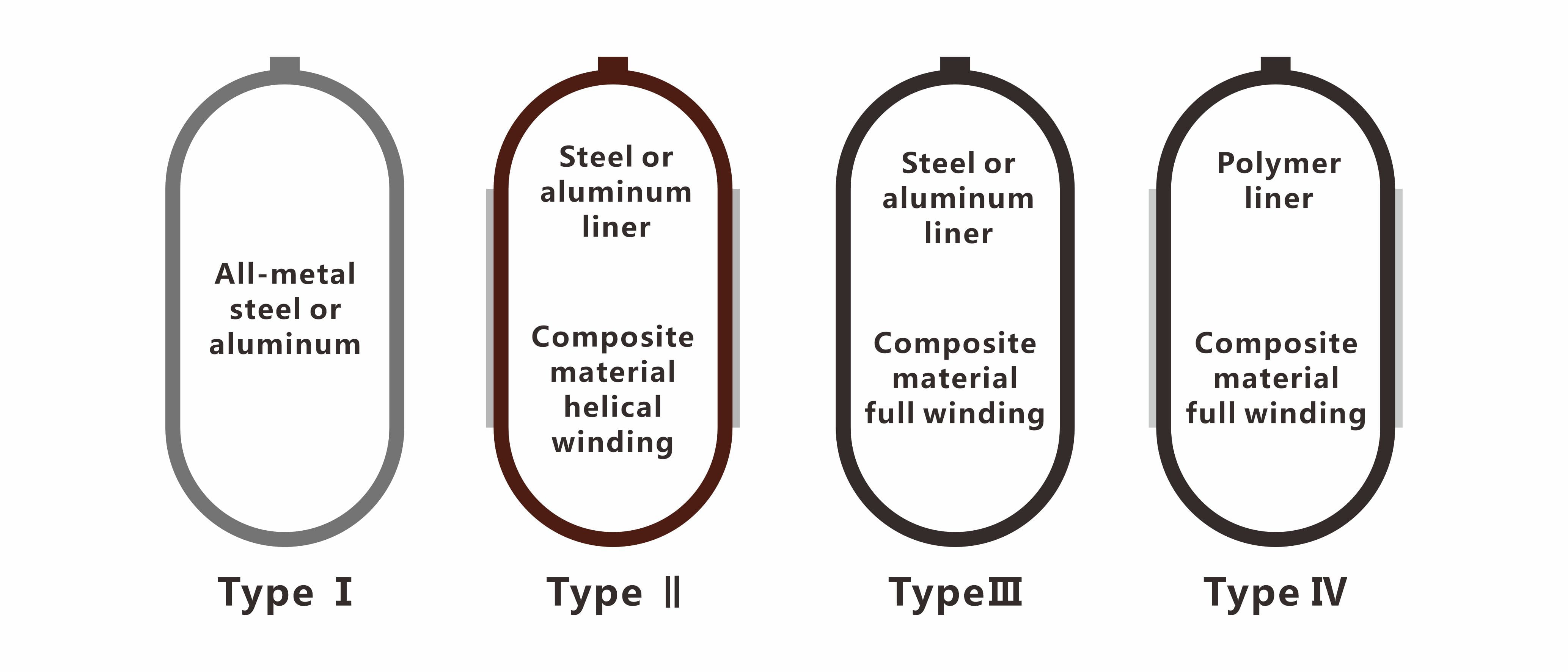

- Safer, plastic liner does not exist grain boundaries, will not occur stress corrosion and hydrogen embrittlement;

- The pressureis higher,35/70MPais widely used;

- High mass density of hydrogen storage, more than 20% higher than the three-type bottle;

- Low weight, three type bottle liner weight is larger;

- The cost is lower than the three-type bottle products, and theinner liner material is different;

- The fatigue performance is good, and the fatigue life is more than 2 times longer than that ofthe three-type bottle

- The product with the same diameter and volume has small weight, low weight ratio and good economic benefit

| Implementation standard |

Norminal Working

Pressure(Bar)

|

Hyd.test Pressure

(Bar)

|

Filling medium

|

liner material |

Diameter

(mm)

|

Nominal water volume

(l)

|

Length(mm) |

Weight(kg) |

|

GB42612-2013

ISO19881:2013

|

350 |

525 |

compressed hydrogen |

PA |

425 |

220 |

2150 |

90 |

| 580 |

390 |

2150 |

142 |

On-board hydrogen supplysystem

Anhui Clean Energy has been dedicated to the research and development of high-pressure hydrogen cylinders for CH4 composite gas cylinders. After relentless efforts by our technical team, we successfully developed 35MPa and 70MPa high-pressure hydrogen cylinders in 2024. To further enhance product quality, we invested 300 million RMB in 2023 tobuild an automated plant, At the same time, our goal is to produce 35MPa and 70MPa high-pressure hvdrogen cylinders that meet domestic and international high standards and launch them to the market by 2025

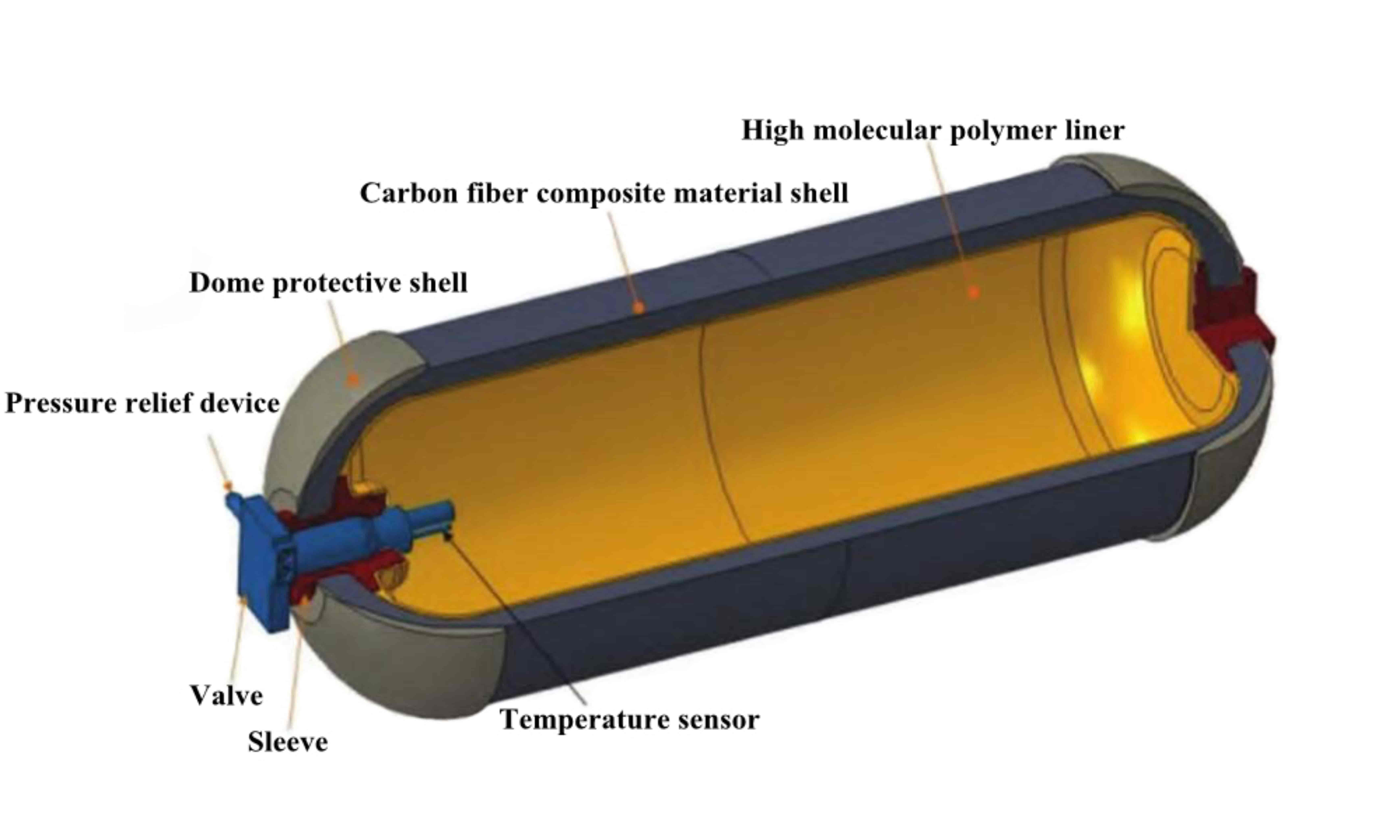

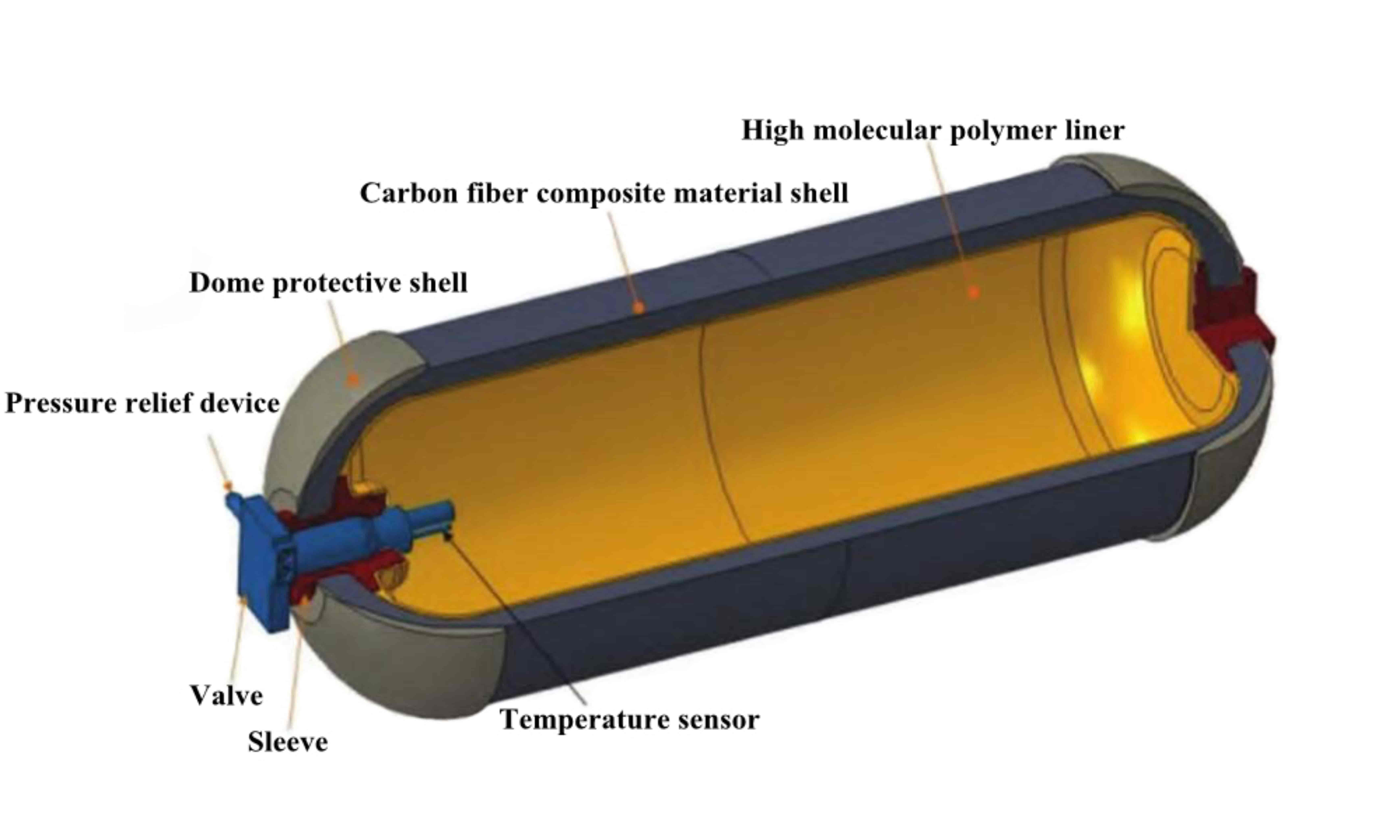

Product principle ofvehicle hydrogen supplysystem

It is composed of carbon fiber fully wound hydrogen storagebottle, combined bottle valve, filling port, pressure reducingvalve,pressure/temperature sensor, etc.

NorminalWorkingPressure:350bar/700bar

Outlet pressure:2.5-20bar(adjustable)

| Model number |

Pressure rating

(Mpa)

|

Number of cylinders

(only)

|

Cylinder volume

(L)

|

Gas storage capacity(kg) |

Operating temperature(°c)

|

| LD02v100A |

35 |

2 |

100 |

6.3 |

-40~85 |

| LD02v210A |

35 |

2 |

210 |

13.3 |

-40~85 |

| LD03v166A |

35 |

3 |

166 |

15.7 |

-40~85 |

| LD04v166A/B |

35 |

4 |

166 |

15.7 |

-40~85 |

| LD06v166A/B/C |

35 |

6 |

166 |

31.4 |

-40~85 |

| LD08v166A/B |

35 |

8 |

166 |

41.9 |

-40~85 |

| LD10v166B |

35 |

10 |

166 |

52.3 |

-40~85 |

| LD12v166B |

35 |

12 |

166 |

62.8 |

-40~85 |

| LD04v140A/B |

35 |

4 |

140 |

17.7 |

-40~85 |

| LD06v140A/B/C |

35 |

6 |

140 |

26.5 |

-40~85 |

| LD08v140A/B |

35 |

8 |

140 |

35.3 |

-40~85 |

| LD10v140A/B |

35 |

10 |

140 |

44.1 |

-40~85 |

| LD12v140A/B |

35 |

12 |

140 |

53 |

-40~85 |

| LD14v140A |

35 |

14 |

140 |

61.8 |

-40~85 |

| LD02v68v28A |

70 |

2 |

68/27 |

8.6 |

-40~85 |

| LD06v134A/B/C |

70 |

6 |

134 |

50.7 |

-40~85 |

| LD08v134A/B |

70 |

8 |

134 |

67.6 |

-40~85 |

| LD10v134B |

70 |

10 |

134 |

84.5 |

-40~85 |

Quality Control

Our products have ISO 11439, ISO11119, ISO9089, UN ISO9809, ECE R110, EN11245 and other international certificates, as well as the company's own ISO9001 and IATF 16949 and other international quality system certificates. We know that you want to keep improving the quality of your products. We, on the other hand, focus on details, on quality. Because we believe that every smallest step affects the value and quality of the final product.

Since its establishment over ten years ago, the company has a self-built factory covering an area of 56,000 square meters. We currently have a workforce of 240 employees, including 50 senior technical and management personnel. Additionally, we possess the production capacity to manufacture 300,000 various types of gas cylinders per year, as well as 9,000 sets of CNG framework assemblies and gas supply systems.

Language :

Language : English

English français

français español

español

IPv6 network supported

IPv6 network supported