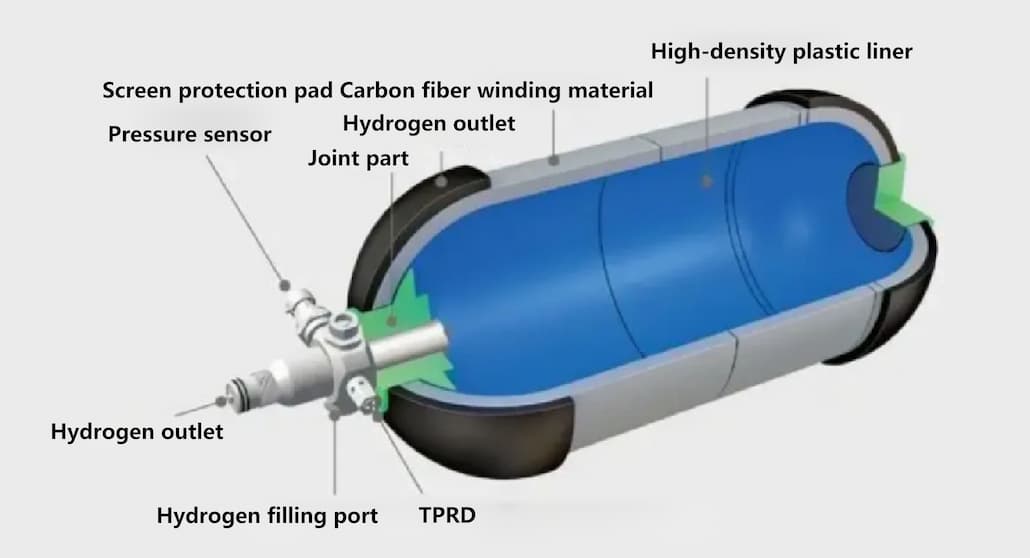

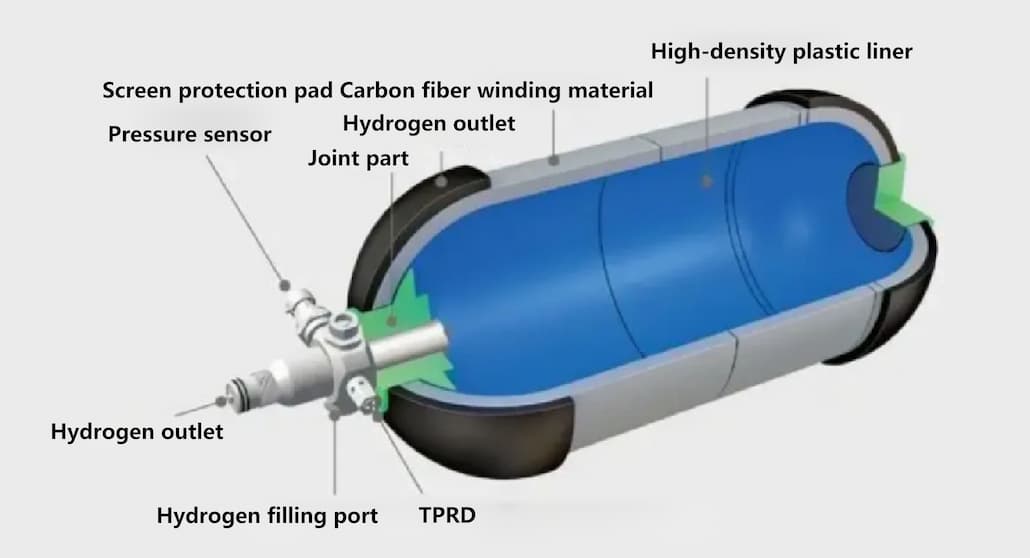

High pressure hydrogen bottle is usually composed of bottle body, bottle valve, safety device and other parts. The cylinder body is the main part of the storage of hydrogen, which is generally cylindrical and has a head at both ends. The bottle valve is used to control the inlet and outlet of hydrogen and the flow regulation. Safety devices such as safety valves, bursting discs, etc., are used to release hydrogen when the pressure is too high to ensure the safety of the cylinder

Manufacturing high pressure hydrogen cylinder material needs to have high strength, high toughness, good corrosion resistance and can resist hydrogen brittleness. Commonly used materials are high-strength alloy steel (such as chromium molybdenum steel), aluminum alloy, composite materials (such as carbon fiber reinforced composite materials) and so on.

The fully wound gas cylinder produced by Clean Energy pressurized hydrogen gas plastic inner liner for vehicles is lined with outer wound fibers and forms a strong reinforced structure through a curing process. In the fiber wound pressure vessel, only the fiber can bear the external load, and the bearing capacity of the matrix is not considered. The fiber winding methods include annular winding and longitudinal winding

Carbon fiber is commonly used for the winding layer. The buffer layer material should have the following requirements: ① good shock and vibration resistance; (2) Small compressive creep and permanent deformation; ③ The temperature and humidity sensitivity of material properties are small; (4) No chemical reaction with the coating layer and fiber of the container; ⑤ Easy manufacturing, processing and installation, low price; ⑥ Low density; ⑦ Non-flammable

Safety performance: High-pressure hydrogen cylinders need to be able to withstand high internal pressure, and the general working pressure can reach 35-70MPa or even higher. In the process of design, manufacture and inspection, the pressure resistance of the cylinder needs to be strictly tested and verified to ensure that it is safe and reliable under working pressure. Because the hydrogen molecule is small, it is easy to penetrate into the metal material, resulting in the strength and toughness of the material is reduced, and hydrogen embrittleness occurs. Therefore, the material of the high-pressure hydrogen cylinder needs to be specially treated or the material with good hydrogen brittleness resistance is selected to prevent the cylinder failure caused by hydrogen embrittlement. Equipped with safety devices such as safety valve and bursting disc, when the pressure in the cylinder exceeds the set value, the safety device will automatically act to release hydrogen and prevent the cylinder from exploding under overpressure.

Applications: High pressure hydrogen storage applications include large high pressure hydrogen storage containers for transportation, large high pressure hydrogen storage containers for hydrogen refueling stations, high pressure hydrogen storage tanks for fuel cell vehicles, uninterruptable power supplies for communication base stations and fuel cell power systems for drones. At present, high-pressure gaseous hydrogen storage is still the most engineered hydrogen storage technology, and 35MPa and 70MPa are the mainstream high-pressure hydrogen storage tank setting pressure values used by fuel cell vehicles.

Language :

Language : English

English français

français español

español

IPv6 network supported

IPv6 network supported